Over the past two-plus years, global supply chains have been stretched beyond recognition. Yet stretched is not broken, and covid-19 may serve as the launch pad to create a new and improved global supply chain model.

Global supply chains became the norm for most products when labor and materials cost differences across the world permitted products to be produced using global components. This was made possible and accelerated through advances in technologies that improved manufacturing processes and communication, the relaxing of trade barriers between countries, and inexpensive energy that allowed worldwide logistics to be cost competitive.

All these drivers carried with them vulnerabilities, effectively increasing the global supply chain risk calculus.

So when covid-19 struck the world in the spring of 2020, no one could have foreseen the dramatic impact it would have across the entire global supply chain. This included availability of raw materials, disruptions to labor due to stay-at-home orders and people infected, and logistic bottlenecks at ports and via trucking.

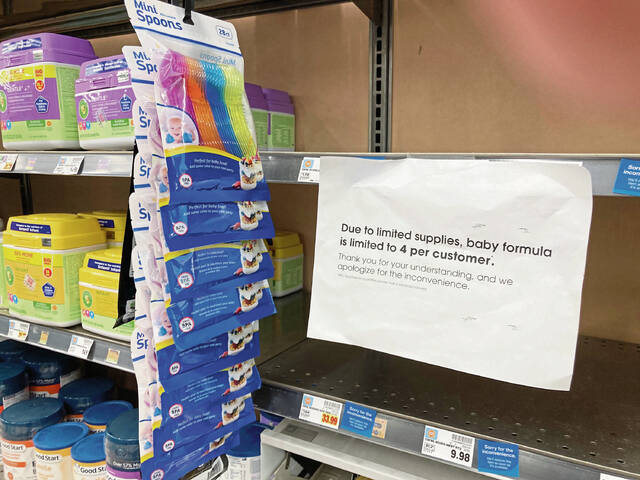

The net result of stretched supply chains has been product shortages and rising prices. Even when products or raw materials were available, traversing the “last mile” and getting them to manufacturing plants or consumers became problematic.

In spite of squawking and naysaying, the societal disruptions inflicted by covid-19 could not have been predicted nor prepared for. Every aspect of global supply chains has been stretched beyond anything that could have been foreseen. Much like a 100-year flood, preparing for it is both costly and highly unlikely to be beneficial, until of course it occurs.

Moving forward, are global supply chains dead? Can they adapt to a world that demands greater robustness? Are domestic supply chains destined to become more ubiquitous because of their perceived greater resiliency? The answer is no.

Covid-19 did indeed expose the weak belly of global supply chains. Yet in a business environment driven by cost reductions and profit maximization, the direct costs of planning for a global pandemic are exceedingly high.

Domestic supply chains are also not the answer. Work force disruptions, raw material shortages and shipping delays can all still occur. In fact, the “Made in America” movement is largely an illusion. Numerous products portrayed as “American” possess significant international components and footprints. It has become exceedingly challenging to avoid global links in supply chains.

In addition, inflation has soared over the past year, with covid-19 its driver. With federal bailouts injecting trillions of dollars into the economy, and a multitude of product shortages, the supply/demand imbalance fueled higher prices. Until this imbalance is leveled, prices will continue to rise, pushing inflation to 40-year highs.

So if covid-19 stretched global supply chains, can it also help to fix them?

Surprisingly, the answer is yes.

Global supply chains have always been vulnerable to disruptions. Covid-19-induced disruptions have been a perfect storm of raw material shortages, workforce shortages and logistic interruptions. Such disruptions have been near biblical, with each feeding on others. Until covid-19 struck, gloomy forecasts of global supply chains crumbling were all theoretical. covid-19 made some of them real.

Yet in spite of the extreme pressure that covid-19 disruptions exerted, the majority of products remained available, though there were delays and short-term shortages. These will continue until an equilibrium is regained.

These disruptions will likely force many manufacturers and producers in global supply chains to pause moving forward. Lean inventories may be fattened to provide some product buffer, even with their added cost. It remains to be seen how long this will be implemented, given that it will impact bottom lines that investors and shareholders may not appreci

External forces that lack the footprint at this time to impact global supply chains are monkey pox and the Ukraine war. If anything, disruptions in China are a bigger threat, given their wealth of raw materials and their manufacturing of numerous low cost products that America appears addicted to. However, even with them, the associated risks are small, given the $300 billion trade deficit the United States has with them and the $1 trillion of U.S. Treasury holdings they own.

Global supply chains are not going away. They offer far too many economic benefits. Most importantly, global supply chains facilitate lower cost products for consumers, something that is essential in competitive markets and demanded by consumers in the marketplace.

It is unfortunate that it took a global pandemic and cataclysmic global supply chain disruptions to expose their weak belly. It is also fortunate that these same disruptions revealed that under the most extreme conditions, global supply chains can continue to function.

It is said “that which does not kill us makes us stronger.” Covid-19 lessons learned have the potential to strengthen global supply chains in the future.

Sheldon H. Jacobson is a computer science professor at the University of Illinois. With a background in probability models, he applies his expertise in data-driven risk-based decision-making to evaluate and inform public policy.