Some of the physical sets that audiences see on theater stages here and across the country began inside the Pittsburgh CLO’s Construction Center for the Arts in Springdale. More than 50 musical theater sets, ranging from classics such as “1776,” “The Sound of Music” and “Annie” to blockbusters “Mary Poppins” and Disney’s “The Little Mermaid,” are waiting to be onstage. A few are owned by other theater companies or co-owned with the CLO.

Since 1974, the center has constructed scenery with a staff of designers, technicians and skilled craftspeople not only for the CLO’s summer seasons and Cabaret Theatre, but also for other theaters, ballets, operas and film and television sets all over.

There is a set from the “Music Man” that was built in 1994.

When the Pittsburgh CLO disposes of an older set, it holds onto props, so thousands of items are stacked on shelves with labels identifying the contents, which include clocks, police nightsticks and clubs, hair and beauty products, books, manual typewriters, musical instruments and coat racks.

Pretty much anything you can think of can be found here: There are puppets, mannequins, a mophead animal and butterfly from “Dr. Dolittle” and various body parts … yes, body parts.

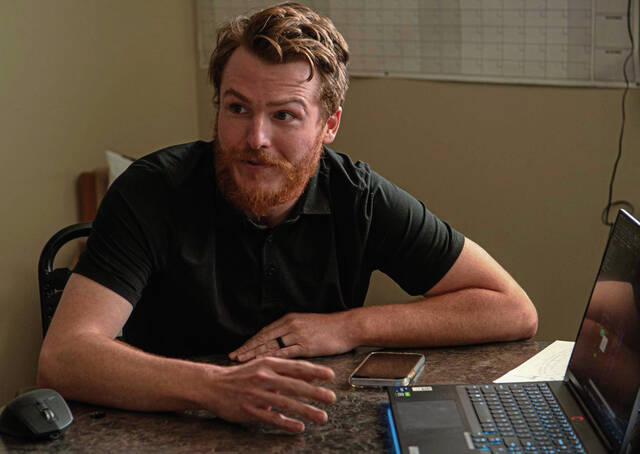

“It’s a chaotic mess that’s organized,” said John R. Edkins, director of production and technical supervisor of the Pittsburgh CLO Construction Center for the Arts, as he gave a tour of the 68,000-square-foot warehouse that’s filled with items piled close to the ceiling. “We know where every piece is in the warehouse.”

The space includes a carpentry shop, setup area and paint deck. It also encompasses 42,000 square feet of storage space for long- or short-term rental.

Edkins, who has been in theater for more than three decades, and his son, Jordan Edkins, shop foreman and technical director, discuss upcoming performances with CLO executive producer Mark Fleischer and show designers for other productions. They learn all the details and formulate a budget. They purchase most materials from local companies.

Through virtual design, physical walls are created via a computer numerical control router. It can cut anything from wood and plastic to aluminum or foam. In the past, everything was done by hand. The machine can do in a day what used to take weeks.

The pieces are connected with hinges. They are decorated by scenic artists who use water- based acrylic paints to create a backdrop.

Parts appear to be one piece because they fit like a glove. For functionality purposes, they need to be easily assembled and disassembled. It is important that pieces fit through doors and can be loaded onto a truck or trucks with ease for traveling.

“It’s like a big puzzle,” Jordan Edkins said. “We design it, and then they (the craftspeople) build it.”

The shop is preparing for the CLO’s summer season, which opens June 13 with “Anything Goes” at the Benedum Center in Downtown Pittsburgh. The center, which will make all six sets, is working on sets for “Once on This Island” and “Natasha, Pierre & the Great Comet of 1812” and building parts for “Anything Goes.”

This is a busy time because of high school musicals, summer theater seasons throughout the U.S. and international shows.

The CLO Construction Center has rented sets in Australia, Japan and China. Sets have made their way to Broadway in New York. The center has produced scenery for “Les Miserables,” Michael Jackson and Rolling Stones tours, HBO, NBC television and the movies “Mrs. Soffel” and “Flashdance.”

It built the only authorized replica of the Vatican creche in conjunction with the Diocese of Pittsburgh that is displayed every Christmas at the USX Plaza, Downtown.

The shop hires International Alliance of Theatrical Stage Employees Local 3, stagehands and professional scenic artists for not only the CLO’s summer season but for other regional performing arts organizations, national tours and musical theater productions throughout the U.S.

There is a space to view the final product before it goes on tour to debut on opening night.

“It is really cool when you have the logistics to pull a show together and see it onstage,” John Edkins said. “The goal is to make everything crisp and clean. The important thing is to stay focused and stay on course because one slight error of wrong judgment call can put you behind for weeks.”

The construction center serves as a storage facility for some of today’s musical theater sets while providing a rental program available to theaters. The center rents sets because it costs a lot to build them, Fleischer said. An average set costs between $100,000 and $300,000 to build. This does not include a theater’s masking or stage curtain (part of a theater’s own inventory), which could cost upward of $300,000, as well.

The average cost to rent a set is between $15,000 and $30,000 per week.

“The money goes back into making sets and other programs we do,” Fleischer said. “A big part of the vision for the construction center is to rent pieces out to other companies. It helps everyone. This is a service to the community. It all works together.”

Kati Gigler, acting executive director of Pittsburgh Ballet Theatre, said the construction center is an amazing resource for arts groups.

“We have worked with them numerous times,” Gigler said. “Most recently, they built a giant set out of steel and plexiglass for our performance of Helen Pickett’s ‘The Exiled.’ The set was essential to the work, and it had a tremendous impact on audiences.”

When a set leaves the center, usually Jordan Edkins or his father travel with the crew to make sure everything is assembled properly. Each part is labeled, and there is a “bible” that has setup instructions. It usually takes one to three days to put it together and eight to 10 hours to break it down.

Like most businesses, technology helps things run more efficiently such as the timing of the release of each panel that collapses for the set during “The Play That Goes Wrong.”

“Automation is a big part of our business,” John Edkins said. “The panels can be set to fall in a certain sequence. Often, the panels get damaged when they fall. When that happens, we know what to do. We can repair the panels.”

Because, as they say, the show must go on.